FIBERGLASS REINFORCEMENT

Fiberglass reinforcement successfully replaces the traditional steel reinforcement in many concrete structures.

BASALT-PLASTIC REINFORCEMENT

Basalt plastic reinforcement is produced on the basis of basalt fibers and polymer components.

SANDED REINFORCEMENT

Sanded reinforcement is one of the varieties of non-metallic reinforcement, sand coating increases the adhesion index.

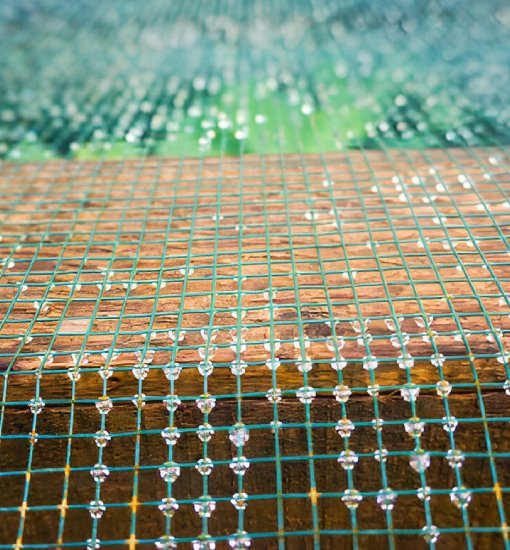

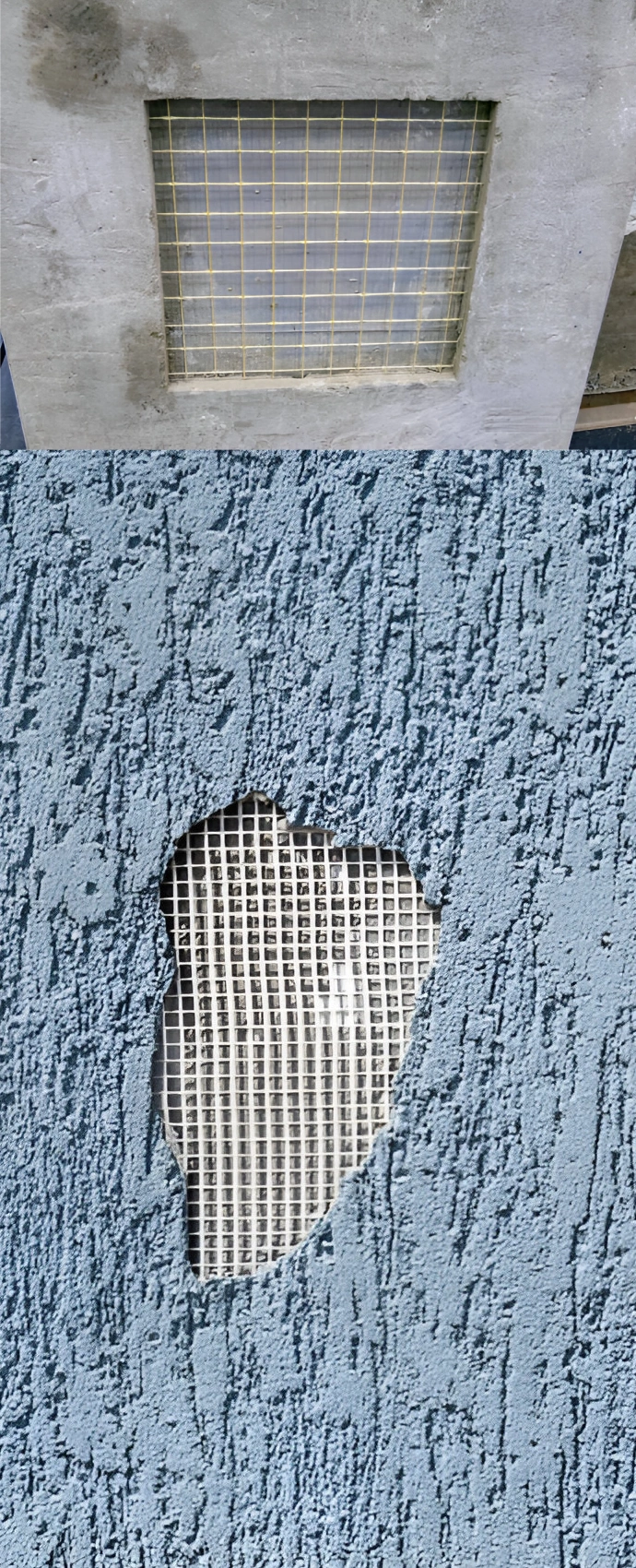

FIBERGLASS GRID

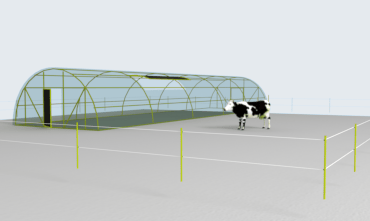

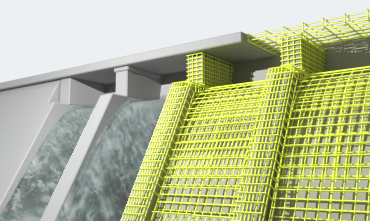

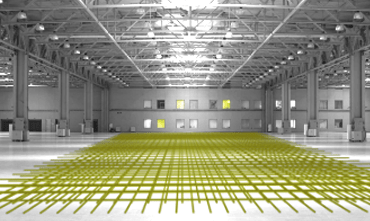

Reinforcing element, made of rods of different cross-section. It is an excellent replacement for metal reinforcement in industrial, civil and road construction. Do not fail through alkalis and moisture.

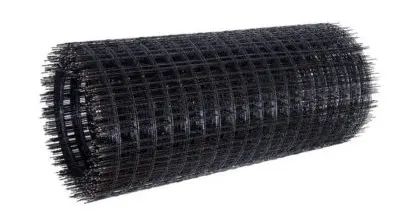

BASALT-PLASTIC GRID

Basalt plastic mesh is not subject to corrosion. It is an excellent replacement for metal reinforcement in industrial, civil and road construction. It is practical and simple in installation.

BASALT GRID

Basalt grid is extensively employed in both civil and industrial construction, functioning as an innovative coil mesh for reinforcement and a versatile bond mesh for secure structural connections.

FIBERGLASS FLEXIBLE TIES

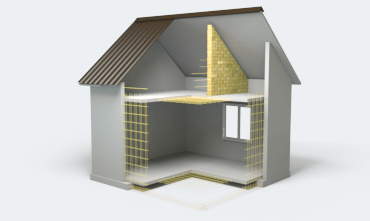

Elements perform several functions at once. They significantly increase the heat efficiency of walls, reduce heat loss, eliminate “cold bridges”.

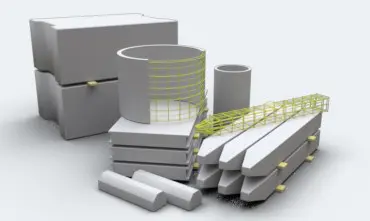

CHAIRS FOR REINFORCEMENT

Basalt and fiberglass reinforcement are fixed with the help of different elements. The company “Armastek” implements several types of chairs.

SANDED

FLEXIBLE TIES

Flexible ties prevent the destruction of walls and increase the strength of the building. You can significantly reduce construction costs through the using of these elements.

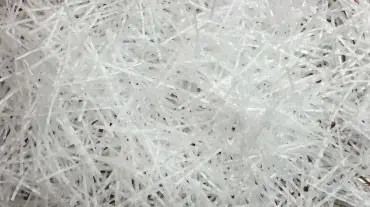

POLYPROPYLENE MACROFIBER STRUCTURAL

Structural macrofibre is made from an unique raw material. Structural texture of the material allows to firmly adhere to concrete giving it strength, resistance to wear, prevents cracks, as a result increases the durability of the structure.

BASALT FIBER

Short pieces of basalt fiber, meticulously engineered for disperse three-dimensional reinforcement, are ideally suited for enhancing the structural integrity of concrete and various cement. These fibers promote uniform load distribution and boost durability and performance across a wide range of building applications.

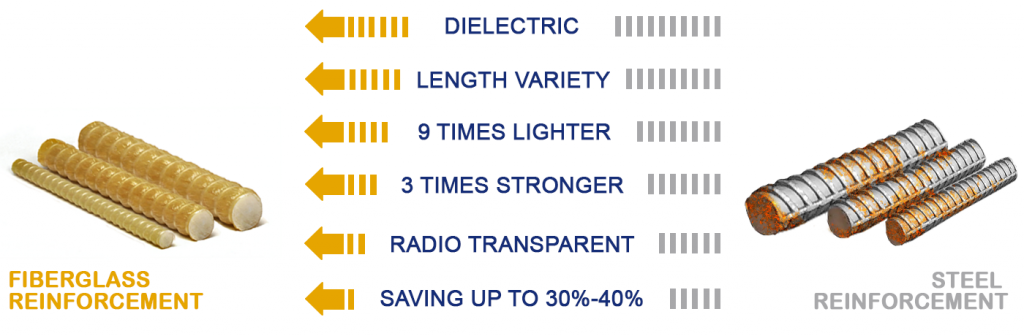

Advantages of fiberglass reinforcement

Applications (composite reinforcement)

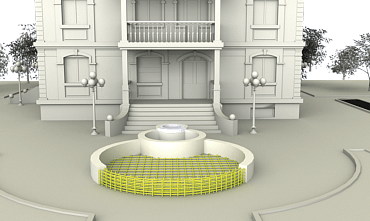

Building

Reinforcement for Foundations

Agriculture

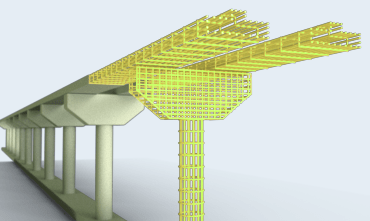

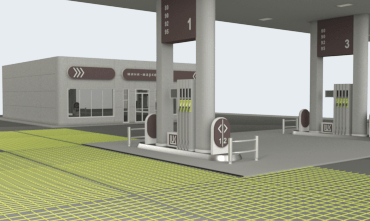

Road Construction

Bank Strengthening

Wall Reinforcement

Infrastructure Facilities

Special Purpose Objects

Industrial Engineering

Production of Fiberglass Reinforcement

The company “Altasleeh Alrdeef” is a major manufacturer of composite reinforcement and mesh. The company’s products are supplied to several countries and are in demand. Composite reinforcement is used in different constructions. The material has a number of advantages over traditional steel reinforcement.

Types of composite reinforcement:

Composite reinforcements are fiberglass and basalt plastic products.

Fiberglass reinforcement successfully replaces steel bars in construction. Due to the use of this material it is possible to reduce the cost of the structure. Fiberglass reinforcement is used not only in civil engineering – it is used for the construction of transport, hydraulic and special facilities. The reliability of this material has long been proven in practice.

Production:

The company “Altasleeh Alrdeef” has its own production facilities. The production of fiberglass reinforcement requires modern equipment and careful quality control at every stage. We can guarantee high quality products. Our production facilities are located in three cities. One of the sites is located in Slovakia, two – in Russia. The company has European quality certificates and an international dealer network.

In addition to fiberglass and basalt plastic reinforcement, we can offer fiberglass and basalt mesh, reinforcing mesh and other products. Products are produced by the company’s proprietary technology.

New generation equipment:

For customers who wants to produce their own products, we can offer our own equipment for the manufacturing of reinforcement and mesh. These are production lines of new generation and meet the most stringent safety requirements. We produce products for over 10 years using our own technology and we ourselves use similar lines for manufacturing of high-quality fiberglass and basalt plastic reinforcement.

Together with the equipment, the client will receive technology for production. This is a turn-key of business, you do not need to develop technology yourself or pay for it separately.

Compliance and Certification

Altasleeh Alrdeef has quality certificates

International brand

Export of products to 15 countries

Production capacity

36 million running meters per year

International Dealer Network

More than 50 representatives in the world